Have you ever had the internet go down while working on an important document? It’s one thing to twiddle your thumbs until the internet’s back online. It’s another thing when all of your hard work goes down the drain. While most companies try to adopt a proactive mindset, reactive maintenance is the industry norm. If that’s the case, why is reactive maintenance considered bad and why is proactive maintenance considered good? Keeping reading to find out why.

Reactive Maintenance

Someone with a reactive mindset will wait to perform maintenance until an asset fails or is close to failure. For example, let’s say your car breaks down on the highway because you forget to change the oil. No one wants to deal with their insurance company or the repair costs if they don’t have to. A reactive approach to maintenance has several disadvantages:

- Faulty machine parts can damage other components on the asset.

- It is expensive and time-consuming to reorder and receive parts that are not in stock.

- A technician might need to grab a part from another work order to perform emergency repairs.

- The machine decides when it is time to perform maintenance rather than the technician.

A reactive maintenance strategy is only desirable under certain circumstances. For example, when it costs less to replace a piece of equipment rather than maintain or repair it. If you want to run your equipment to failure, be sure whether the desired benefits outweigh the potential risks.

Proactive Maintenance

Someone with a proactive mindset will plan, schedule, and complete work ahead of time so that an asset can be used like it’s new. For example, let’s say you have a bearing that’s starting to grind. If you are the proactive type, you might lubricate that bearing to increase its lifespan or replace the bearing before it fails. A proactive approach to maintenance has several advantages:

- Schedule when downtime happens, making it easier to perform maintenance on a single part while keeping the rest of a machine intact.

- Use planned downtime to take care of other mission critical maintenance activities.

- Review an asset's work order history to schedule routine preventive maintenance ahead of time.

- Make sure all of the parts, procedures, tools, and proper crafts are available when work is needed.

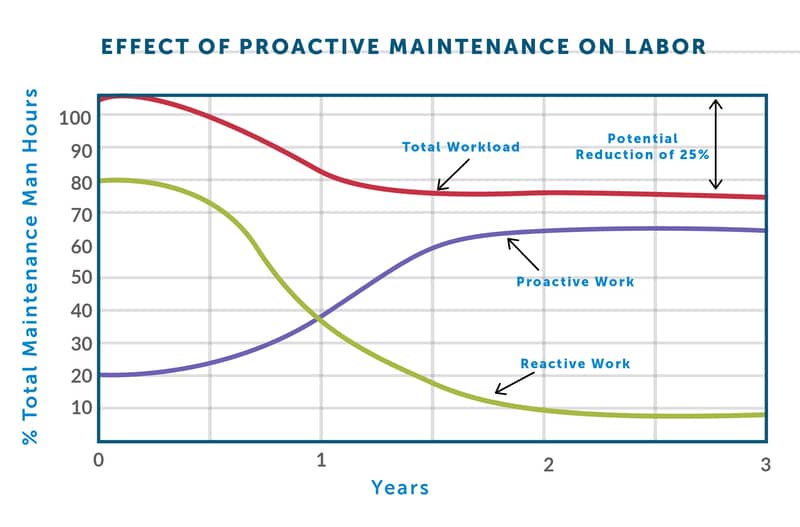

The graph above illustrates how a proactive mindset can save your maintenance department time and energy. For example, when companies struggle to stay profitable (like during an economic downturn), they often cut labor costs by laying off employees. Unfortunately, maintenance is usually the first department on the chopping block because the department is typically viewed as a cost center rather than a profit center; a necessary evil if you will.

What management often fails to recognize is how proactive maintenance can reduce labor costs by increasing the efficiency of existing resources while reducing headcount through attrition. Did you know that proactive maintenance can reduce a company’s total workload by up to 25%? By being proactive, you can actually remain profitable without laying off anyone. Why spend money rehiring and retraining when you don’t have to?

How Proactive or Reactive Is Your Department?

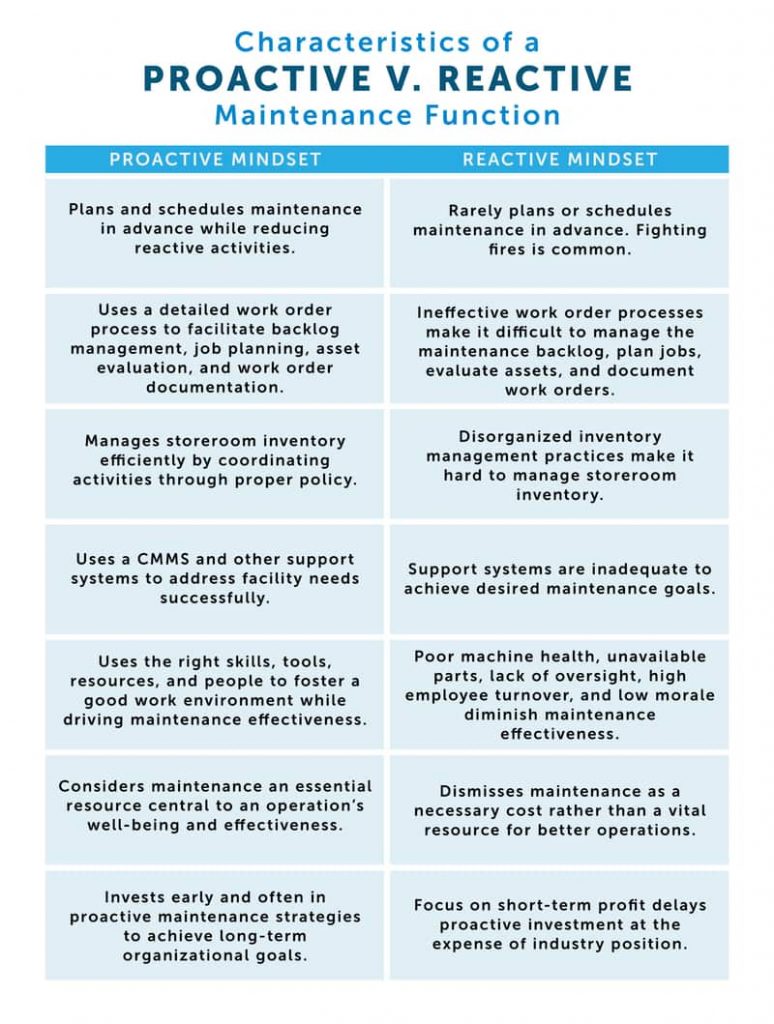

If we haven’t already made this clear, it’s super important to figure out whether your maintenance department is proactive or reactive. To do this, just compare the percentage of emergency / reactive work to planned / proactive / predictive work.

Remember, proactive maintenance is often a more productive, efficient, and economical approach to maximizing equipment effectiveness, and it honestly produces incredible results if your company is willing to invest in the facility’s long term well being and stick to the program.

Look No Further, We Are Here to Help!

CMMS Data Group’s Reliability Engineering Division offers a variety of services aimed at helping organizations achieve world-class maintenance & reliability. One place to start is the Maintenance Excellence Status Assessment (MESA). MESAs give organizations the steps needed to transition their maintenance function from a cost center to a profit center. Contact us today for more information!

About CMMS Data Group

Founded in 2000, CMMS Data Group is the market leader in CMMS software and services. Led by the award-winning MVP Plant™ CMMS software combined with its professional services and technical support, the Company also provides comprehensive Reliability Engineering Services. These solutions empower maintenance and reliability professionals to increase customer satisfaction, reliability, capacity, productivity, and profitability, delivering a competitive edge to their organization.